SMT

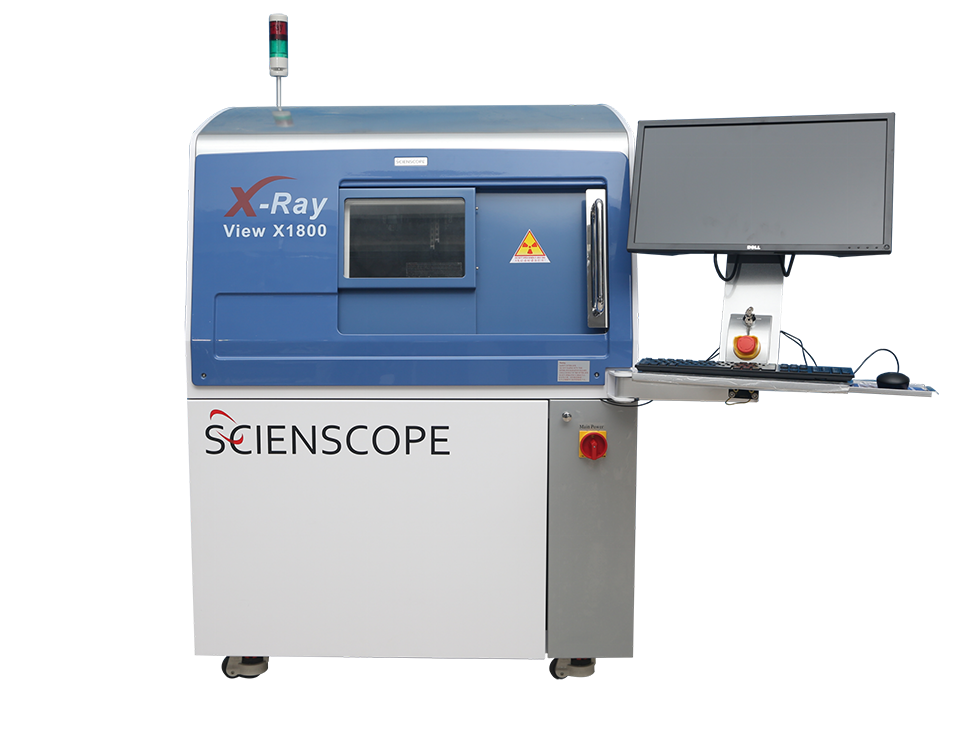

There are 9 original Japanese Panasonic placement machines in the SMT workshop, which are equipped with intelligent feeding, optical inspection and intelligent temperature control reflow soldering production lines. Automatic online AOI quality detectors, X-Ray detectors and X-ray automatic material dispensers. Currently, it has 12 million dots / day patch production capacity. Bonding: Equipped with 6 automatic ASM macro bonding machines and a COB packaging capacity of 30,000 pieces / day.

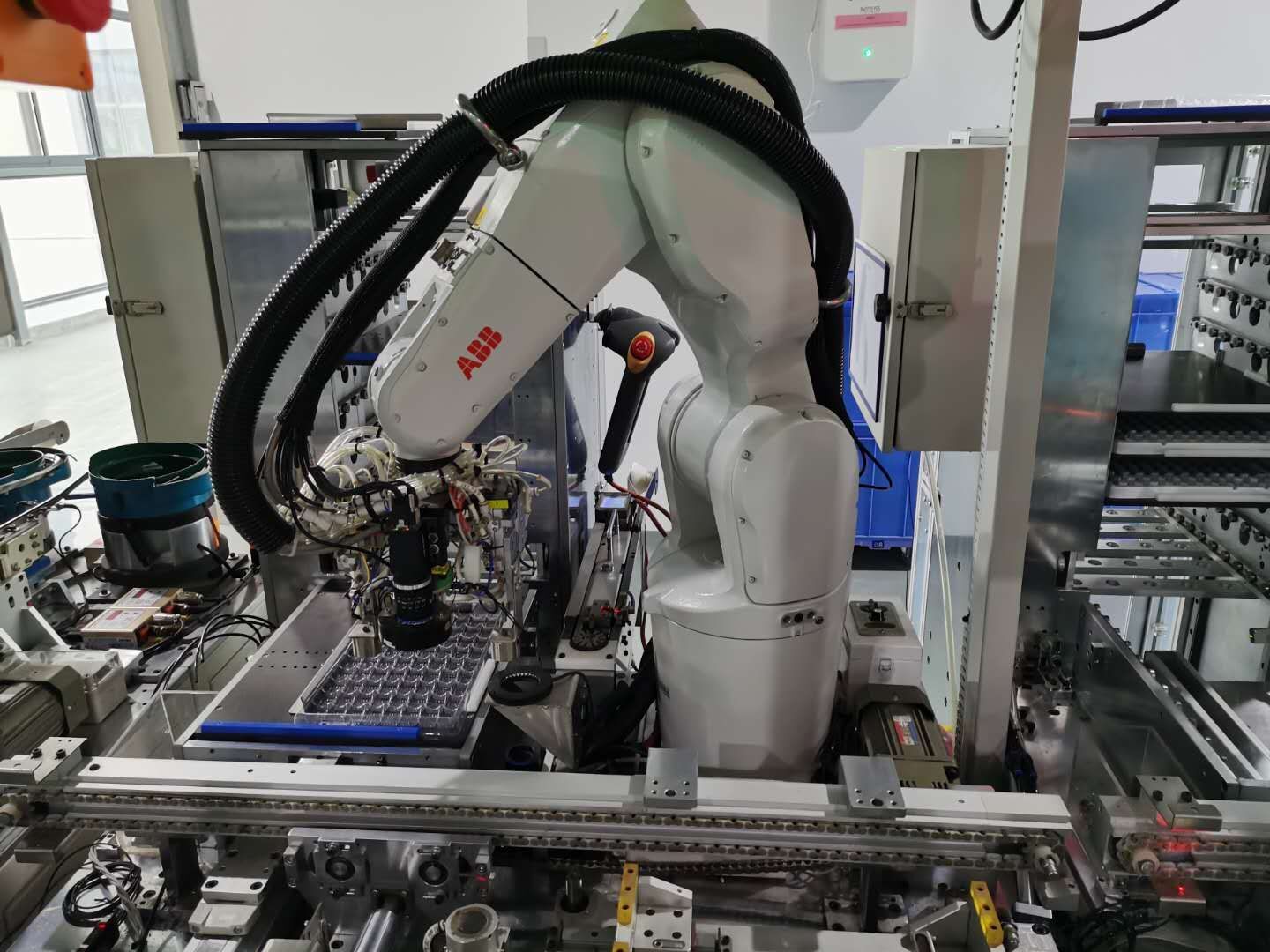

Dip: A customized automatic robot Dip production line to meet the automatic production of conventional and special-shaped components, PCB three anti-paint coating process.

Guide

KingChuang 2019Service and Product Guide booklet, easy to read and choose all the services you need to provide

Download《KingChuang the 2019 Guide》

Download《KingChuang the 2019 Guide》

-

X-Ray X-ray detector

-

Shansi X-RAY testing equipment

-

Panasonic NPM

-

GKG automatic solder paste printing machine

-

device

-

workshop

-

AXC-800III

-

Panasonic NPM placement machine

-

DIP workshop equipment

-

DIP workshop

-

DIP workshop

-

COB solid crystal machine

-

Microscopic examination

-

COB sealing machine

-

Tunnel furnace